Safety

A message from the chair…

Western Canada Tire Dealers Safety Committee

Our committee is comprised of a group of professionals that are dedicated to the safety of all workers, regardless of their company. We are a transparent group that is more than willing to help the competition with a safety procedure, policy, or even provide assistance. If we have it, we are more than willing to share it.

Our goal is to ensure the safety of our workers and to share information including incidents that occur to increase awareness among others in the same industry, thus keeping everyone safe, regardless of their employer. By sharing safety alerts, we can educate all workers and make others aware of potential hazards. If it’s happening at one shop, it’s happening somewhere else. We have just been fortunate enough to not have a serious incident.

Our committee meets quarterly, and if needed, we communicate more often via email. Once a year we meet face to face and have some really great discussions. We are always looking for more committee members to join our group to enhance awareness and education for all. If you are interested in joining our committee, please contact the committee chair Tim Pawsey – timp@wctd.ca.

Safety – what’s it all about?

Not only is safety legislated by the government but it is a way of doing business and a part of what we do in our everyday lives. Simply put, safety is a procedure that is designed to keep you from harm.

Under safety legislation, all workers have 3 basic rights: the right to know (about hazards in the workplace), the right to participate (in safety meetings, inspections, etc) and the right to refuse (unsafe work).

However, employers have obligations too. Employers are required to: ensure that workers are aware of the hazards that they are being exposed to, and to train and educate workers.

So, what’s next?

A lot of people think that safety is “hard to do” and is “a lot of work”. When you get down to the basics, the concept is pretty simple. Say what you do, do what you say and document what you do.

Say what you do – develop policies and procedures to show employees how the work is to be completed and what is expected of them.

Do what you say – hold safety meetings, train and orientate your employees, ensure that workers are using the safe work practices and safe job procedures that are developed for those tasks and complete inspections.

Document what you do – keep records of your safety actions such as training, safety meetings, and inspections. If you cannot prove that you have done safety tasks, by way of documentation, it’s as if you didn’t do it. Completing regular internal audits will assist in ensuring compliance with your existing program.

Once you have everything in place it’s simply a matter of maintaining those standards and with a positive safety culture at your location, it will become increasingly easier to maintain that program.

Safety Bulletins

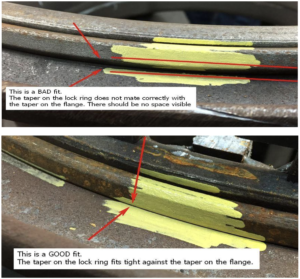

Some purchased LR25T Lock rings were found to be defective

As reported by North Shore Wheel

Scope: It has been found that one batch of LR25T 3-piece Lock rings manufactured on June 5th, 2014 and stamped “LR25T 14 156” have a manufacturing defect. These Lock rings were rolled wrong.

Corrective Action: North Shore Wheel is recalling all LR25T 3-piece lock rings that have been stamped LR25T 14 156. Please refer to my e-mail for any purchases made by your company and advise if you have them in stock or where they are located in the field. North Shore Wheel will then do what is necessary to have them replaced.

Preventive Action: North Shore Wheel will no longer be purchasing the Old Style LR25T lock rings, and will use this opportunity to acquire and supply the New LR25T Style Lock Ring.

Tire blows off rim during install

What happened?

A tire technician was installing three tires on three new rims. The first two went as planned. When he was installing the third tire he grabbed the wrong rim. When he started to inflate the tire it blew off the rim.

Why did it happen?

The employee attempted to install a 16-inch tire on a 16.5-inch rim. The employee was airing up the tire on the tire machine when it blew apart. The employee’s hand was cut and he was taken to the hospital where he required 4 stitches to close the wound.

Corrective Action or Preventative Measures Taken

An important part of the Tire Industry Employee (TIA) training specifically addresses the issue of ensuring that 16” tires are not installed onto 16.5” rims. Ensure that all employees are paying attention to the tasks at hand.

Injury to face during tire inflation

Incident Description

A team member was installing a 425/80r25 new Bridgestone tire on a bed truck on the truck pad. Team member installed the tire on the wheel and attached the air chuck and began inflating with no tire restraint. When the beads were seated the lock ring dislodged from the tire and struck the team member’s hip and face. The injured team member will require a number of major dental surgeries to repair his teeth.

Investigation Key Points

- The team member had not been properly trained on 3 piece wheel assemblies

- Wheel components were not cleaned prior to mounting

- The lock ring was installed upside down

- The tire/wheel was not restrained

- The team member was in the trajectory zone during inflation

Learning Points

1. All wheels MUST be inflated in a restraining device i.e. T-lock, tire cage or truck mounted crane

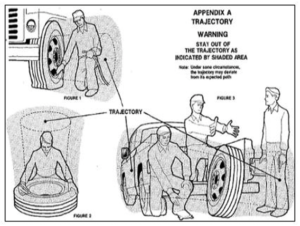

2. All team members MUST remain out of the trajectory zone when inflating tires

3. All team members must be trained and signed off by a mentor prior to performing their job duties/tasks.

4. Safety glasses, gloves, steel-toed boots, and hearing protection must be worn during inflation

5. Proper inspection – all tires/wheels must be thoroughly inspected and cleaned inside and out prior to mounting

6. Never assemble a tire and rim unless you have identified the correct components

7. If you are unsure about a process or task speak up and ask for clarification or help

8. Components must be properly matched and correctly installed and verified prior to inflating

Serious zipper incidents resulting in injuries

In the past 2 months, there have been 3 serious zipper incidents resulting in injuries to team members.

Incident 1

A team member was airing u tire using a remote inflator and a Tp a 11R24.5 Michelin Recap lock for restraint. He reached in to install the valve core and the tire zippered at 90100 psi. The team member was taken to the hospital by ambulance and sustained a bruised chest and lacerations to his face.

Outcomes: Inadequate training and poor/lack of tire inspection the tire showed visual signs of run-flat. Investigation revealed the team member did not fully complete the first 24 hr. orientation. Corrective action was conducted against the store manager.

Incident 2

A team member was fixing a flat repair on a wheelbarrow tire; the tire was overinflated by 40psi which caused the tire to blow as the team member was removing the air hose. The team member sustained cuts and bruising to his right hand.

Outcomes: Team member was in the trajectory zone; he left the airline on and walked away from the job.

Incident 3

A team member was airing up a 1100R20 backhoe tire lock for restraint; he reached in to check the pressure on the tire and the tire blew. He was taken to the hospital by ambulance and sustained bruising to his arm and lacerations to his face.

Outcomes: Overinflated the tire and the tire showed signs of run-flat. The team member was in the trajectory zone.

Important Reminders

- All team members must be trained prior to performing their duties

- Stay out of the trajectory zone when inflating a tire

- All wheels must be inflated in a retraining device i.e. T–lock, tire cage or truck mounted crane

- Safety glasses, gloves, steel-toed boots, and hearing protection must be worn during inflation

- Proper inspection all tires must be thoroughly inspected inside and out prior to mounting

Figure 1 Trajectory Zone

Figure 2 What’s wrong with this picture?

Answer:

- No PPE

- No remote inflator

- In trajectory zone

Anything else?

Always dismount the tire and look for signs of a “run-flat” ask your mentor or refer to your training for more

Bead seater tank explodes causing injury to a worker

Recently a bead seater tank exploded causing injury to a worker.

Please check with your bead seater tank distributor for manufacturers’ recommended Inspection, Maintenance, Storage, Disposal and Operating Instructions.

The Motor Safety Association encourages you to always follow the manufacturer’s recommendations.

Contact Us

Address

Western Canada Tire Dealers

65 Woodbine Rd.

Sherwood Park, AB

T8A 4A7

Follow Us

©2023 Western Canada Tire Dealers | Site design by Mighty Sparrow Design